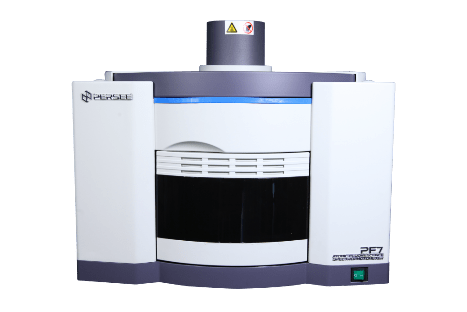

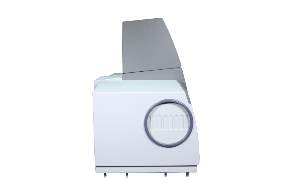

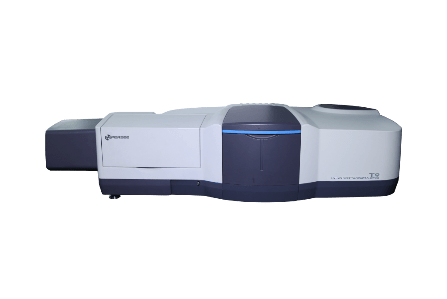

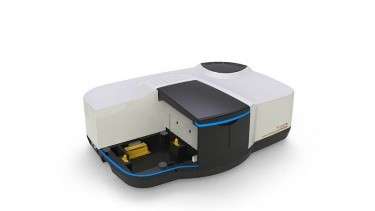

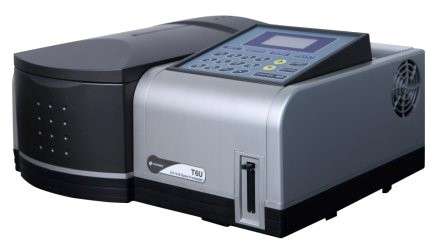

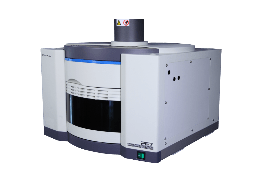

AA990AFG

AA990AFG is an atomic absorption spectrophotometer that combines the flame and graphite furnace into one instrument. It integrates the sample atomization methods of air-acetylene flame, hydride generation, and graphite furnace electrothermal heating. The instrument is operated automatically using the AAWIN software, making it highly automated, safe, and reliable. It is particularly suitable for industrial, mining, and vocational teaching applications.

| Product Name | AA990AFG

|

| Product Description | AA990AFG is an atomic absorption spectrophotometer that combines the flame and graphite furnace into one instrument. It integrates the sample atomization methods of air-acetylene flame, hydride generation, and graphite furnace electrothermal heating. The instrument is operated automatically using the AAWIN software, making it highly automated, safe, and reliable. It is particularly suitable for industrial, mining, and vocational teaching applications. |

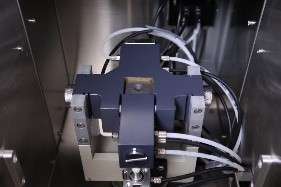

| Features | The instrument has a motorized 8 hollow cathode lamp turret which allows the automatic positioning and optimization of each hollow cathode lamp by the software. The control of the gas flows for the fuel gas (C2H2) of the burner is also carried out directly from the software thus allowing optimization of the instrument for the analytical parameters for a selected analysis. Two methods of background correction are available. The first utilizes a Deuterium Arc lamp and the second is the proven method of Self Reversal. High precision minimal optics ensures maximum light throughput to the computer controlled Czerny-Turner Monochromator. The location of the wavelength and peak selection is automatically controlled from the software The spectral bandwidth is automated and is available with a choice of five slit sizes. The electronic parameters for the photomultiplier tube detector, the hollow cathode lamp current and the balancing of the absorbance and background energies are controlled from the software. The ignition of the flame is computer controlled and the various safety interlocks offer a very safe operating system.The unique design of the graphite furnace reduces the chemical interference effects and memory effects by uniformly heating the graphite electrode.– Automatically switch between the flame atomizer and graphite furnace atomizer– Automatic positioning and optimization of each hollow cathode lamp– Control the fuel gas flows of the burner to optimize the best analytical parameters– Control the Czerny – Turner Monochromator – Locate the wavelength and select the peak – Control the electronic parameters of the photomultiplier tube detector and hollow cathode lamp current – Balance the absorbance and background energy – Control the ignition of the flame – Optimize the best heating program ◆ Integrated safety precautions for user protection by following: – Burner Switch – Flame Sensor – Gas leak Sensor – Drain Trap Sensor – Power Loss Protection – Circulation Water (graphite) – Over Temperature Sensor (graphite) ◆ Precision accuracy with integrated correction system ◆ Life cycle value, best choice for less than 8 elements of analysis |

| Principle | The flame conditions are continuously monitored and should the flow rates change, an audible alarm sounds

The pressure of the support gas (oxidant) is monitored constantly. If the pressure changes then the flow of the fuel gas will be stopped and the flame will be safely extinguished A sensor monitors the level of liquid in the drain and will prevent ignition if too low. The flame will also be extinguished if the level of liquid in the drain changes significantly. A flame sensor monitors the flame and safely turns off the gas flow to the burner if the flame suddenly extinguishes. The transverse heating method can provide a good time and space constant temperature environment during the atomization process of the graphite tube, to improving the atomization efficiency and test accuracy, and ensure that the analysis results are more accurate. At the same time, it reduces the requirement of furnace body and prolongs the service life. The analysis of metallic elements is conducted based on the absorption of characteristic radiation by atomic vapor in its ground state. This method can sensitively and reliably determine trace or trace elements. Elements are atomized by heating in a flame or a thermal decomposition graphite furnace, forming atomic vapor in its ground state. This vapor selectively absorbs the characteristic radiation emitted by a hollow cathode lamp. Within a certain concentration range, the absorption intensity is directly proportional to the content of the measured element in the test solution. The quantitative relationship can be described by the Lambert-Beer law, A = -log(I/Io) = -log(T) = KC, where I is the intensity of transmitted light, Io is the intensity of emitted light, T is the transmittance, L is the optical path length through the atomizer (which is fixed for each instrument), and C is the concentration of the sample being measured. Therefore, A = KC. The device used to measure the absorbance of atomic vapor through the resonance radiation of the element being measured is called an atomic absorption spectrophotometer. Its basic structure includes a light source, an atomizer, an optical system, and a detection system. It is mainly used for the analysis of trace elements and impurities, and has the two major advantages of high sensitivity and good selectivity. It is widely used in the analysis of trace elements in various gases, metal organic compounds, and metal alcohol salts. |

| Application | Agricultural and environmental protection field: It can be applied in agriculture to complete the detection of food, seeds, vegetables, soil, pesticides, etc.

Research and Education: AA990AFG is used for various research work and departments in University. Geological exploration field and mining: Applied to general investigation of geological mines, detailed inspection and abnormal evaluation. Environmental testing field: Complete the detection of water quality, atmosphere, rainfall and soil according to national standards, and determine the content of pollutants Commodity inspection, food inspection field: It is used for the control of industrial production process and the analysis of organic and intermediate products, such as the detection of cosmetics, meat, aquatic products, alcohol, oral liquid, tea and other products. Metallurgy: Detection of harmful elements or impurities in metals Administrative agencies, Government:Applied to the detection of heavy metal elements in water plants, sewage treatment plants, power plants, judicial organs, etc. Petrochemical: Process control of petrochemical production, finished product testing, etc.

|

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

1.png)

.png)

1.png)

.png)

1.png)

.png)

1.png)

.png)

1.png)

.png)

.png)